Company Profile

The Original Manufacturer of Physical Therapy Equipment in China

Jiangsu ALPHAY Medical Device Co., Ltd. was founded in 2006 and is a technology-based enterprise dedicated to the R&D, production, and sales of health and medical products. Located in Nantong City, which is thriving and known as the “Northern Shanghai”. After more than 18+ years of development, Alphay Medical has created two major product lines, namely household massagers and household medical braces. We focus on the treatment and massage of bone disease-prone areas such as the waist, neck, and knee joints, in order to provide assistance to those who suffer from pain. Fortunately, we have achieved this goal.

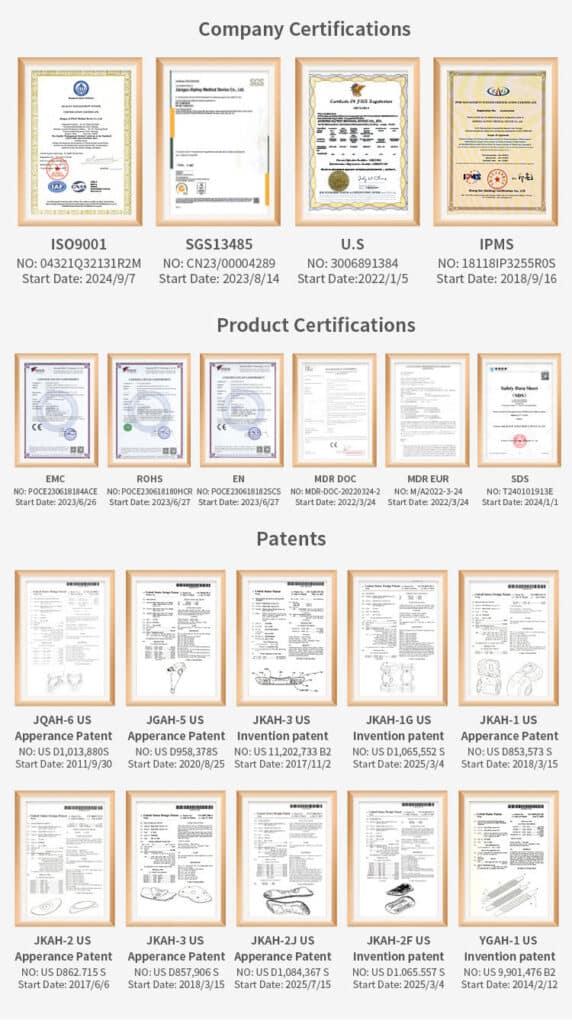

Certifications

ISO13485, FDA, CE and TGA Certifications

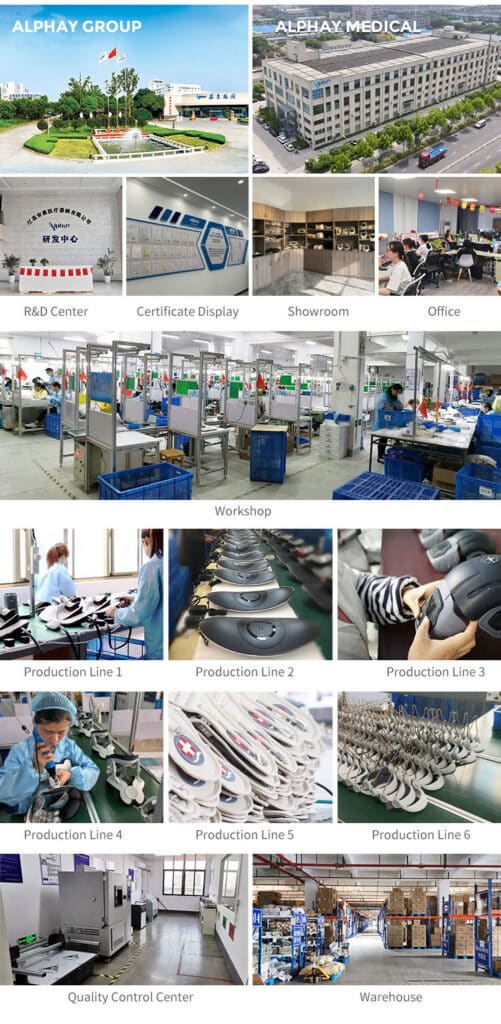

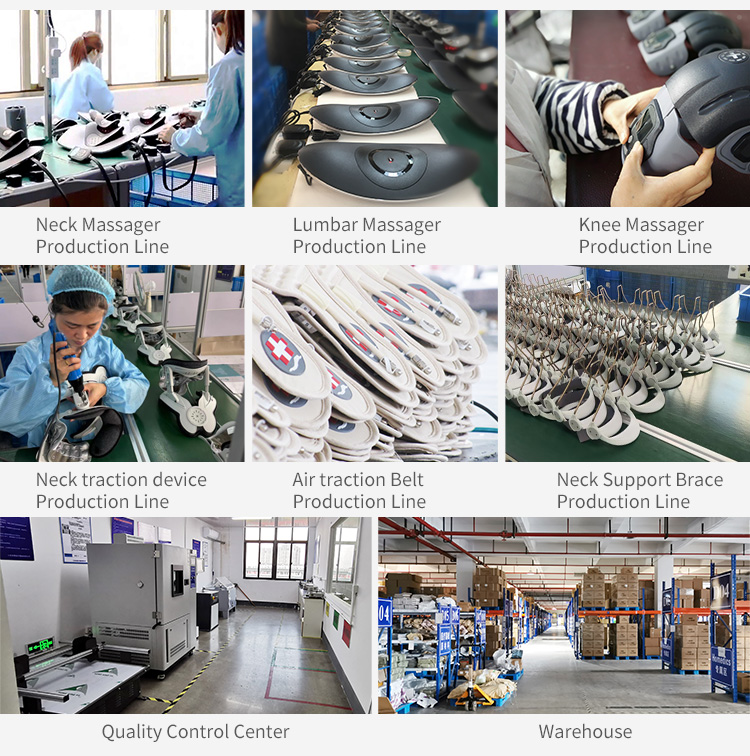

Factory Show

Exbitions

Our Clients From 150+ Countries

Quality Control

Raw Material Inspection

Only the qualified raw materials will be put into production. When the raw materials enter the warehouse, the QC shall inspect the raw materials according to the strict inspection standards. Qualified raw materials will be sealed off. The inspection date, supply date, and supplier will be marked.

Functional Testing

Every machine completed from the production line will be placed in the testing area. The QC will turn on the machine and let the machine run automatically, ensuring that each function of the machine meets the requirements (such as traction height, heating temperature, etc.). All products can only get into the packaging process after passing the functional testing.

Production Automation

Engineers will install electrical components, valves, motors, pumps, and other parts on the base of the machine according to the production process requirements. The fully automatic screw machine can fix the screws according to the set coordinates, reducing manual error.

Salt Spray Testing

Adjust the salinity of different proportions through a salt spray testing machine to test the tolerance of product components in different simulated environments. And ensure that the product functions perfectly during long-term sea transportation.

Impact and Balance Testing

The outer shell of the product is made of high-strength plastic, which can meet the testing requirements of the falling ball testing machine. The QC will test the plastic strength by dropping the ball onto the machine according to the test height standard. The balancing machine detects the dynamic balancing ability of the product to ensure that the product quality meets the safety regulations and use requirements.

High & Low Temperature and Vibration Testing

When developing new products, the R&D team conducts high and low temperature testing on the new products through high and low temperature test boxes(-40 ℃-80 ℃), simulating whether extremely hot or cold storage environments will affect the machine. Transport vibration table testing products in the long-term shipping process of various functions to maintain perfect.

Company Culture

- Company Profile

- Certification

- Factory

- Exbition

- Quality Control

- Company Culture

The Original Manufacturer of Physical Therapy Equipment in China

Jiangsu ALPHAY Medical Device Co., Ltd. was founded in 2006 and is a technology-based enterprise dedicated to the R&D, production, and sales of health and medical products. Located in Nantong City, which is thriving and known as the “Northern Shanghai”. After more than 18+ years of development, Alphay Medical has created two major product lines, namely household massagers and household medical braces. We focus on the treatment and massage of bone disease-prone areas such as the waist, neck, and knee joints, in order to provide assistance to those who suffer from pain. Fortunately, we have achieved this goal.

ISO13485, FDA, CE and TGA Certifications

Originality and quality are always what we insist on. Our products are ISO13485, FDA, CE, ROHS, TGA certificated. All our products are designed and manufactured by ourselves and patented in USA and China. At present, the patent applications of our new products are in procedure.

Quality Assurance

Alphay medical factory has rich production lines and more than 200 employees, ensuring reliable and consistent production of high quality products. Our products meet the relevant standards for export to Europe, America and other countries, so our customers can rest assured that they will be receiving the hgh quality product available.

Our Clients From 150+ Countries

We value our clients more than anything else, they are precious treasures that are treasured by alphay medical. Through our customers, we bring our idea “life can feel good again ” to over the world.

Our commitment to them is unwavering, and we strive to provide them with the best possible service and experience.

Quality Contrl

Raw Material Inspection

Only the qualified raw materials will be put into production. When the raw materials enter the warehouse, the QC shall inspect the raw materials according to the strict inspection standards. Qualified raw materials will be sealed off. The inspection date, supply date, and supplier will be marked.

Functional Testing

Every machine completed from the production line will be placed in the testing area. The QC will turn on the machine and let the machine run automatically, ensuring that each function of the machine meets the requirements (such as traction height, heating temperature, etc.). All products can only get into the packaging process after passing the functional testing.

Production Automation

Engineers will install electrical components, valves, motors, pumps, and other parts on the base of the machine according to the production process requirements. The fully automatic screw machine can fix the screws according to the set coordinates, reducing manual error.

Salt Spray Testing

Adjust the salinity of different proportions through a salt spray testing machine to test the tolerance of product components in different simulated environments. And ensure that the product functions perfectly during long-term sea transportation.

Impact and Balance Testing

The outer shell of the product is made of high-strength plastic, which can meet the testing requirements of the falling ball testing machine. The QC will test the plastic strength by dropping the ball onto the machine according to the test height standard. The balancing machine detects the dynamic balancing ability of the product to ensure that the product quality meets the safety regulations and use requirements.

High & Low Temperature and Vibration Testing

When developing new products, the R&D team conducts high and low temperature testing on the new products through high and low temperature test boxes(-40 ℃-80 ℃), simulating whether extremely hot or cold storage environments will affect the machine. Transport vibration table testing products in the long-term shipping process of various functions to maintain perfect.

We are always sticking to the idea “Quality is the culture”. In the future, ALPHAY is confident to be more professional, more convenient and more trustworthy. We are glad to make friends all over the world and enjoy the experience together.